Versatile, powerful, precise.

This website no longer functions correctly in the Internet Explorer. Microsoft has discontinued the support for Internet Explorer 11 - it is considered obsolete and is no longer recommended due to security reasons and for lack of compatibility. Change to a new browser now to be able to correctly use the functions of the website

Groove cutting machine NFU 50: Versatile, powerful, precise.

Groove cutting machine NFU 50 offers flexibility of use and is an all-rounder capable of executing an enormous range of timber construction tasks. An extensive range of accessories opens up further possibilities for day-to-day work.

Groove cutting machine NFU 50: A wealth of different applications

With its exemplary material and build quality and intelligent practical features, the NFU 50 is a versatile all-purpose machine. It enables you to save time and energy, and invest your working resources instead in getting the job done well.

Groove cutting machine NFU 50: Perfection in every detail.

The design of the NFU 50 is characterized by the use of extremely rugged, high-quality and precision-made parts, including the lightweight magnesium die-cast housing and impact-resistant, fiber glass-reinforced plastic components. It also features clever technical details to help you meet the rigors of the job.

Groove cutting machine NFU 50 : Perfection in every detail.

An extensive range of accessories makes the job easier and speeds up working with the NFU 50. Teamed with the high-capacity extractor S 200, incorporating dust extraction unit S 35 M, it is the perfect partner for timber construction work.

Technical data

|

Nominal voltage |

230 V |

|---|---|

|

Nominal power input |

2300 W (3.1 hp) |

|

Cutting depth |

0 – 50 mm (0 in. - 1 15/16 in.) |

|

Tilting range |

0 – 45° |

|

No-load-Speed |

5900 1/min |

|

Weight |

9,4 kg (20.7 lbs) |

|

Dimensions (W x L x H) with guide L |

370 x 810 x 280 mm (14 9/16 x 31 7/8 x 11 in.) |

|

Cutting length with guide L |

370 mm (14 9/16 in.) |

Delivery specification

Groove cutting machine NFU 50

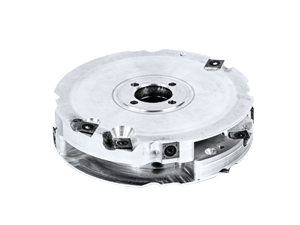

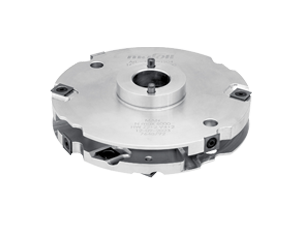

1 cutter head Ø 163 x 60 mm (6 7/16 x 2 3/8 in.)

1 position indicator NFU-PA

1 parallel fence

1 side fence SA 625

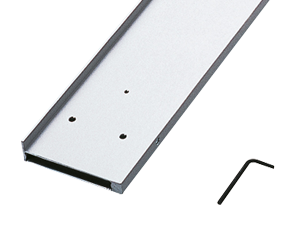

1 guide track L

2 repeat fence

1 allen key SW 6

1 screwdriver Torx T15

1 main cable 10 m (32.8 ft.)

Ref. No. 918701

Guide rail

3.0 m (9.8 ft) (one part)

Ref. No. 200672

3.0 m (9.8 ft) (2 parts + connecting piece)

Ref. No. 037037

1.5 m (4.9 ft) extension

Ref. No. 036553

Pair of adapters

for parallel fence

Ref. No. 037195

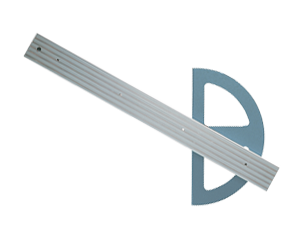

Angle fence F-WA

Ref. No. 205357

Guide rail F

F 80 - Length 0,80 m

Ref. No. 204380

F 110 - Length 1,10 m

Ref. No. 204381

F 160 - Length 1,60 m

Ref. No. 204365

F 210 - Length 2,10 m

Ref. No. 204382

F 310 - Length 3,10 m

Ref. No. 204383

Accessories

Connecting piece F-VS

for joining

two guide tracks

Ref. No. 204363

End caps F-EK

2 pieces

Ref. No. 205400

Non-slip profile F-HP 6,8M

6.8 m long (22.3 ft.)

Ref. No. 204376

Splinter guard F-SS 3,4M

3.4 m long (11.2 ft.)

Ref. No. 204375

Bag for guide rail

Guide rail bag

TZ-FST for guide rails

up to 1,6 m

Order No.095257

Guide pocket set

F 80 + F 160 + F-WA + F-VS

+ 2 x F-SZ 180MM

+ Guide pocket

Order No. 209592

Guide pocket set

2 x F-SZ 180 MM

+ 2 x F 160 + F-VS

+ Guide pocket

Order No. 209591

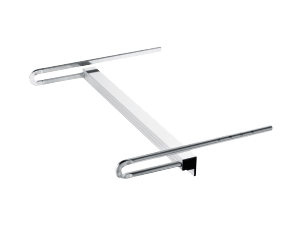

[EN] Universal guide

Compound miter rail

Ref. No. 202069

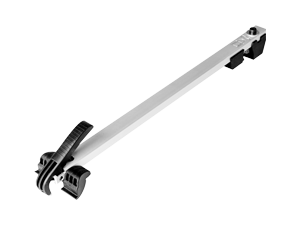

Lever clamp F-SZ 180MM

2 pieces, for fixing rail to work piece

Ref. No. 207770

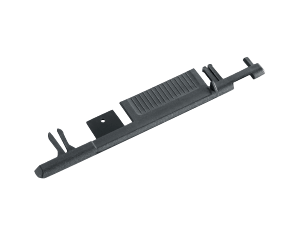

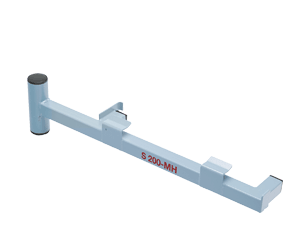

Machine holder

S200-MH

Ref. No. 207164

Roller edge guide

K85-UA

Ref. No. 205166

Parallel fence

K85-PA

Ref. No. 205323

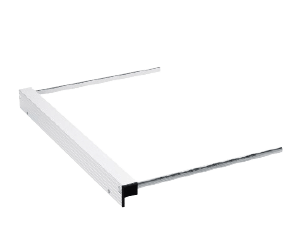

Side fence SA 625

Ref. No. 207183

Cutter head

Ø 163 x 60mm Ref. No. 091901 (6 7/16 x 2 3/8 in.)

Ref. No. 091901

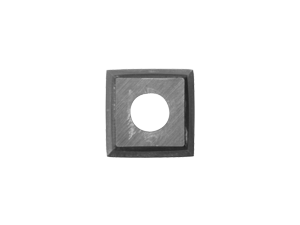

Reversible knives (12 required)

Cutter head

Ø 163 x 46 mm (6 7/16 x 1 13/16 in.)

Ref. No. 091902

Reversible knives (12 required)

Expanding groove cutter

Ø 163 x 22 bis 40mm

(6 7/16 x 7/8 x 1 9/16 in.)

Ref. No. 091899

Reversible knives (12 required)

Expanding groove cutter

Ø 163 x 15,4 - 28,4 mm

Ref. No. 091904

Reversible knives (12 required)

Reversible knife

14 x 14 x 2 mm

(9/16 x 9/16 x 1/16 in.)

Ref. No. 201927

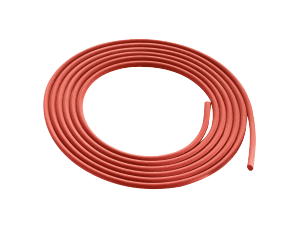

Extraction hose

Ø 49mm (1 15/16 in.) with hose connector

58mm (2 5/16 in.), Ø 66mm (2 5/8 in.) bayonet

catch, static dissipative 5m (16. 4 ft.)

Ref. No. 093730

Milling depth calculation

Calculate the lever position for setting the milling depth (Z), the length (X) and the centre width (Y). The values are calculated from the milling depth and the milling angle.